Day 10 was perhaps the best foodie day of them all!

It was our last day in Parma and right after breakfast we had a tour of the co-op that produces Parmesan cheese. This co-op is run by 5 small farmers who are only interested in producing top quality. Since we already had been on the farm for the last two days, that tour was done. Parmesan cheese is made with non-fat, raw milk, salt and rennet. There are no preservatives like other cheeses, such a Grana Padano, or American Cheese. The cream from the Parmesan cheese is pasteurized and then used for a special butter from Parma. Leftover whey from the production gets used as pig feed for the Parma Ham, and in this way they are connected.

It was our last day in Parma and right after breakfast we had a tour of the co-op that produces Parmesan cheese. This co-op is run by 5 small farmers who are only interested in producing top quality. Since we already had been on the farm for the last two days, that tour was done. Parmesan cheese is made with non-fat, raw milk, salt and rennet. There are no preservatives like other cheeses, such a Grana Padano, or American Cheese. The cream from the Parmesan cheese is pasteurized and then used for a special butter from Parma. Leftover whey from the production gets used as pig feed for the Parma Ham, and in this way they are connected.

The milk used to make Parmesan cheese comes from dairy cows that are in the region specified by the Italian government. The cows are well taken care of and have specific food regulations such as how much hay to grass they can eat in a given time of the year. Today's tour started out in the cheese

production area where there were 5 or 6 copper lined, steam-jacketed kettles shaped uniquely for cheese making.

First, the cheese is heated to a specific temperature and the whey from yesterday's production is added. This whey has all the cultures needed for the cheese. Then after being held for a specific time, liquefied rennet is added, and the cheese it held for a while longer while the curds set. Once the curds have set and pass the "clean break," test then the curds are cut using a unique balloon whisk.

production area where there were 5 or 6 copper lined, steam-jacketed kettles shaped uniquely for cheese making.

First, the cheese is heated to a specific temperature and the whey from yesterday's production is added. This whey has all the cultures needed for the cheese. Then after being held for a specific time, liquefied rennet is added, and the cheese it held for a while longer while the curds set. Once the curds have set and pass the "clean break," test then the curds are cut using a unique balloon whisk.

The pieces of curds are cut to the size of rice, then heated again to a specific temperature. Once they achieve the right temperature, the batch is left to cool and the curds fall to the bottom and separate from the whey. Afterward, they use cheesecloth to remove the curds and then the cheese is pressed.

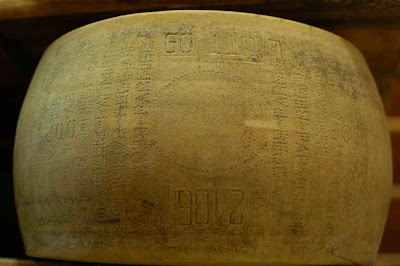

Inside the press, a plastic sheet used to label and date the cheese. This also records the specific origin of the cheese.

Second press.

After pressing the cheeses, they take a bath in a super saturated salt brine for 28 days.

Then left to air dry:

Then the cheese is put in a aging room:

When the cheese ripens, the rind becomes yellow. This takes approximately 2 years. You can see the cheese just below has a date (upside-down) of October, 2009.

This cheese is from May 2009, and has been graded the the Parmesan Consorsium. Thus Consorsium is kinda like a union of parmesan cheese producers who sets the standards for grading and producing the cheese.

The consorsium grades the cheese by flipping it on it's side and tapping it with a hammer to hear the noise in the cheese. This way the can tell if there is a problem.

Cheeses that are not of the best quality, but still tasty, are marked with lines:

After our tour we left our wonderful bed and breakfast, B&B Cancabaia. We hope to see them again someday.

We then headed to a Balsamic producer in Reggio-Emela, outside of Parma. Normally you only see balsamic from Modena, but this small producer is building a case for her balsamic, claiming that Modena has ruined their name by diluting their products with grape must and vinegar. Her products

have been aged a minimum of 12 years, and have nothing else added.

have been aged a minimum of 12 years, and have nothing else added.

We got to see how it is made. First off they use Trebbiano Grapes, which are white grapes, often used in wine making, as well as for making cognac and brandy.

Baby Grapes!

Baby Grapes!

The grapes are pressed for their juice, then the juice is reduced to 1/3 of its original volume. After cooling, the grapes are placed in Oak Barrels that have previously been used for wine making. This is important because the cooking process done to the grape juice kills all the yeast cells needed to ferment the juice, and the barrels contain yeast cells left over from their previous use. The grape juice ferments into wine over the next two years in these barrels.

After two years, the wine is transferred to the largest barrel of five, used to make balsamic. The wine is exposed to the open air through a hole in the top of each barrel. As the product is aged in a non-temperature controlled area, the balsamic evaporates through the barrels, and every other year, the

barrels get filled and the aging process continues. The barrels get filled in a specific way: the smallest barrel is always filled with the next larger barrel, and this continues up the barrel sizes until the two year old wine is added. There are traditionally 5 barrels used and it takes 12 years before they take the smaller barrel and fill bottles, or age it longer. The barrels are made or either oak, juniper, cherry or acacia wood.

barrels get filled and the aging process continues. The barrels get filled in a specific way: the smallest barrel is always filled with the next larger barrel, and this continues up the barrel sizes until the two year old wine is added. There are traditionally 5 barrels used and it takes 12 years before they take the smaller barrel and fill bottles, or age it longer. The barrels are made or either oak, juniper, cherry or acacia wood.

The bottles are filled by a balsamic consortium, much like the ones for Parmesan and Parma ham, to ensure quality.

Because it takes 12 years to sell your product, most balsamic producers also make wine.

Day 10 continued, 11 and 12.

I am calling this my final blog for this vacation. Internet connection has become very hard to come by since coming to Italy. After the balsamic tour, my wife Lauren, and I headed to Florence (Firenze), to see the "David," and some art museums. We we are staying right across Duomo square. The artwork here is amazing, but not really food related, and most of the time they don't allow pictures. But as some do I have a few attached.

I hope my food trek has been interesting for everyone to read. It has certainly been educational for me and although I can't put everything I learned on the blog, I hope you learned something too. If you have questions or comments please feel free to email us!

Ciao!

Because it takes 12 years to sell your product, most balsamic producers also make wine.

Day 10 continued, 11 and 12.

I am calling this my final blog for this vacation. Internet connection has become very hard to come by since coming to Italy. After the balsamic tour, my wife Lauren, and I headed to Florence (Firenze), to see the "David," and some art museums. We we are staying right across Duomo square. The artwork here is amazing, but not really food related, and most of the time they don't allow pictures. But as some do I have a few attached.

I hope my food trek has been interesting for everyone to read. It has certainly been educational for me and although I can't put everything I learned on the blog, I hope you learned something too. If you have questions or comments please feel free to email us!

Ciao!

David

No comments:

Post a Comment